Konjac

Starch with glucomannan as the main ingredient is produced by thinly slicing elephant food, which is the corm of the konjac plant, drying it, grinding it into powder, and removing foreign substances.

This absorbs water and becomes a viscous colloidal liquid. An alkaline coagulant is then added, and it is heated, cooled, and made into translucent jelly or noodles, which is the edible konjac we eat.

*Colloid liquid: Mannan (konjac powder) made by drying, crushing, and milling elephant food is mixed with water to form a viscous liquid.

Limitations of existing ‘konjac products’

Konjac’s unique smell

It has a characteristic strong alkaline odor due to the presence of calcium hydroxide.

Crunchy texture

Due to its unique crunchy texture, you give up the taste and texture.

Weak against heat

When konjac is exposed to hot water above 70 degrees, it shrinks and becomes tough.

Impossible to keep frozen

When konjac is frozen and then thawed, the texture collapses, making it impossible to use it as a raw material for frozen distribution.

Weak against acid

When it comes into contact with acid, the binding force loosens due to neutralization, causing the texture to collapse.

Fermented konjac

Fermented konjac is made by fermenting konjac powder, the main ingredient of konjac, and grain flour using yeast or lactic acid bacteria. This produces sugars, minerals, nitrogen sources, organic acids, alcohol and vitamins, and reduces the unique odor of konjac.

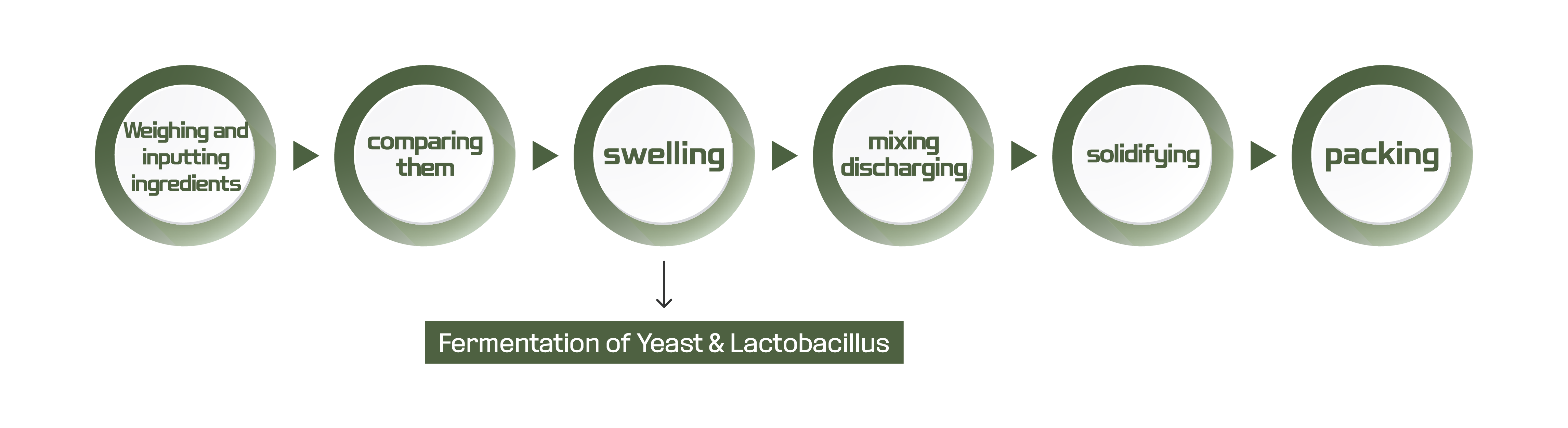

Fermentation process

Through the fermentation process using yeast and lactic acid bacteria for me first time in Korea, We have overcome all the shortcomings of existing konjac products and has experienced the Production line to various products by mixing raw materials that can be stored in heat/acid/freeze.

POINT

Reduction of the konjac odor

The unique odor of konjac is reduced due to the sugar alcohols, organic acids, and minerals generated during the fermentation process.

Chewy yet soft texture

As the dough expands through aging and fermentation, the texture becomes denser, and an air layer is generated in the dough, improving the chewy and soft texture.

Improved sauce adsorption

Carbon dioxide generated during the fermentation process increases the sauce absorption rate through the pores remaining on the surface of the noodles.

Frozen products available

By mixing heat-resistant/cold-resistant raw ingredients, we increased the yield of konjac products and enabled the production of various frozen product lineups.(More than 95% yield in heating production)